Correctional Dinnerware Materials:

What’s the Difference?

Most of the correctional dinnerware on the market looks the same from one supplier to the next and looks like the same stuff that was around 20 years ago. Isn’t there anything new?

The primary thing that has evolved isn’t the shapes and sizes; it’s the material that all of this is made from. A meal tray serves pretty much the same purpose in any environment. However, the unique requirements in the corrections environment calls for special characteristics of the material. Can it break into shards and sharpen into a weapon? How long does it last? What is the max temp it can withstand? What happens if it’s melted? These questions and others have driven the evolution of correctional dinnerware and we have arrived at some pretty novel solutions for facing the challenges of corrections food service.

In the beginning... Let’s skip the scenes from Alcatraz with metal trays and flatware and go right to plastics and cover the progression of material development for correctional dinnerware and the pros and cons of all 7. Are you using the right one for your facility? Let’s find out.

Polycarbonate: This material has been manufactured into dinnerware products for quite some time. Polycarbonate is strong and tough. It has good impact strength, and you won’t have all the little scratches at the bottom of the food compartment that you would with softer materials. It has a more polished look for commercial settings and not so institutional.

Polycarbonate isn’t without its drawbacks though. It has a higher-than-average price tag and a tendency to deteriorate in a wet and warm environment. Over time the repeated heat and moisture cycles will make the Polycarbonate material “craze”, which means to develop hairline fractures in the material (visible in clear plastic products like tumblers). Polycarbonate will shatter after repeated impact stress, after which the pieces harvested from the broken object can be weaponized. The material will bond onto itself and can be sharpened to a razor edge. Polycarbonate should last several years in normal use, but can be adversely affected by both detergents and environment.

Polycarbonate can be a good choice in an ICE facility where you might want more of a cafeteria look than an institution. However, this is not a safe material choice for typical correctional applications.

Co-Polymer: This newer material, made from a blend of polypropylene and impact modifiers, combines durability with extra safety and a low initial purchase price. This material will withstand a wet environment without breaking down. Because the material has more elasticity, it does not generally shatter.

The material does not increase hardness when melted and cooled, so it is very hard to mold into a weapon. When the material is broken, it does not sharpen very well. When melted, it can be shaped into a point, but it is virtually impossible to achieve a razor edge while trying to sharpen. Because the material is somewhat flexible the edges ‘roll’ instead of sharpen.

The major drawback to this material is its aesthetics. Being a somewhat softer material, it does not take very long to build up scratches in the food compartment areas. The scratches tend to stain and make sanitation more challenging.

This material is the most common choice for typical correctional dinnerware applications because it is difficult to make a good weapon with it. It is approximately half the price of polycarbonate and needs replaced about twice as often (due to scratches). So essentially safer for the same net cost. Not always a beauty queen toward the end of their life, but co-poly products are the practical choice for most correctional institutions.

Insulated trays: These products are also made with co-polymer material, so everything said in the paragraph on ‘Co-Polymer’ above is true for this type of product as well. Hope you were paying attention.

The difference in material for insulated trays is the insulating foam at the center. This foam is an expanding polyurethane that is injected as a liquid into the plastic shell. As the foam cures, it expands and fills the interior. The purpose of this foam is to provide insulating properties (R value) that keep hot food hot longer and cold food cold longer. Obviously the primary benefit of this type of tray and material is to maintain food temperatures and give you a little more time to deliver the food at safe food temperatures without using heated carts.

The major drawback to this tray and material type is that eventually the plastic shell gets breached and the many wash cycles will eventually fill the tray with water. The water-logged trays are not sanitary and need to be thrown out and replaced.

The more recent development in materials for this type of tray is to the polyurethane foam. Changes have been made to slightly improve the R-value of the insulating properties. More importantly, additives can be used to make the foam hydrophobic (resist water) to extend their life cycle.

High temperature: This material was developed for applications where the food is re-thermalized in the tray at temperatures typically between 250oF and 350oF for cook/chill operations. The first introduction into the market was Radel-R, the Cadillac. This material has a temperature tolerance over 400oF and has extreme impact resistance. It has excellent scratch resistance and high durability. The only drawback to this material is that it is very expensive (4 to 8 times cost of co-poly equivalent). Lower cost alternatives have been developed as well as offshore alternatives. These materials typically have lower temperature resistance and durability and are still 3 to 6 times the cost of an equivalent co-polymer product.

This type of material is necessary if you operate a cook/chill operation and re-thermalize food in the tray. If your trays never see temperatures above 212oF, it’s best to save the money and go with co-polymer.

Silicone rubber: This material is extremely flexible and has a temperature tolerance of over 400oF. It will not break, crack, or chip. It has good chemical resistance, cleans well, and is flame retardant. For correctional dinnerware, the primary advantage of this material is its difficulty in being made into a weapon while being able to be used in high temperature applications. This material has been targeted for high security use in segregation units, suicide watch cells, and mental wards.

The biggest drawback to this material is cost; it’s 40% to 60% higher than the co-polymer equivalent. Also, the material is floppy and weak. Extra wall thickness is used to stabilize, but that tends to make the trays somewhat heavy and even more expensive. Additionally, this material would not be considered very durable compared to just about any other dinnerware material.

This material is an excellent choice in applications that require high temperatures such as cook/chill re-thermalization in max-security units. If you are only looking for the safety of a flexible material, there are lower cost options; it’s not necessary to pay a premium for high temperature resistance if you don’t need it.

Thermoplastic elastomer: This material was introduced as a lower cost alternative to silicone; about 20% lower. It is intended for applications requiring maximum security where weapon making is a primary concern. Like silicone, it will not break, crack or chip. However, it is not suitable for temperatures over 212oF.

This material is also ‘floppy’ and is not highly durable. Large, flat types of dinnerware like cafeteria trays are not very stable when loaded with food, especially warm food.

This would be a good material choice in most all maximum security applications where weapons making is the number one priority. The only exception is in cook/chill operations that require high temperature material. This material is very safe. Smaller items with tighter geometry like tumblers and segregation trays are most ideal because excessive bending will be less of an issue.

MaxFlex blend: This newest material is a blend of thermoplastic elastomer and certain hardeners that optimize the property trade-off between Shore D hardness (durability) and flexural modulus (safety). Any dinnerware that is made in co-polymer material can be made in this new blend and the functional performance is similar. Its cost is about the same at pure thermoplastic elastomer and about 20% lower than silicone. MaxFlex blend material has two major advantages:

Safety: the material is virtually non-breakable. The elasticity of the material prevents It from fracturing under stress. When taken to its failure point, the material tears rather than breaks. The tear is non-uniform and soft-edged. The edges cannot be sharpened; nor can a piece of material be sharpened into a hard point. When melted and cooled, the material does not harden during cooling but rather returns to the same basic elasticity, preventing weaponization.

Durability: This same elastic property allows the trays to last longer from a functional standpoint. The trays will last as long as they can be tolerated aesthetically. This blended material is more durable than typical ‘flexible’ trays on the market. The Shore D Hardness is almost double that of other ‘flexible’ trays giving it significantly greater durability.

This material would be a good choice for most corrections applications. As safety from weapons making is a concern at some level in almost every corrections environment, this material matches or outperforms everything else on the market. The benefit of greater durability and moderate cost for a flexible safety product makes this a good option for correctional dinnerware.

Which is best?

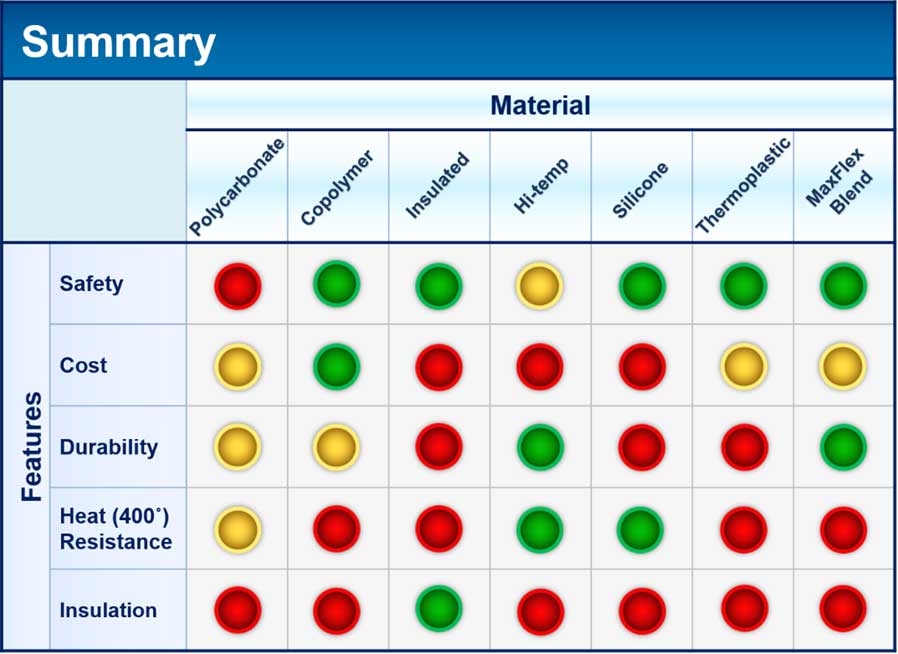

All 7 common correctional dinnerware materials have their own pros and cons, and each can be effectively used in its own situation. The most important things to consider when choosing are safety, cost, durability, and having the necessary temperature tolerance. When considering options, it’s best to get samples and pricing of multiple materials from multiple sources and do the evaluation specific to your priorities.

Here is a matrix to help in your evaluation.

For more information on correctional dinnerware available from JonesZylon.

View Products

For more information on JonesZylon’s new MaxFlex Blend products.

View Products

Want to save or print this article? Download a copy today

PDF

Our Products Are Proudly Made In The USA

Our Products Are Proudly Made In The USA